Apollo Expeditions to the Moon

AN ALL-UP TEST FOR THE FIRST FLIGHT

In 1964 George Mueller visited Marshall and casually introduced us to his

philosophy of "all-up" testing. To the conservative breed of old rocketeers who had

learned the hard way that it never seemed to pay to introduce more than one major

change between flight tests, George's ideas had an unrealistic ring. Instead of beginning

with a ballasted first-stage flight as in the Saturn I program, adding a live second

stage only after the first stage had proven its flightworthiness, his "all-up" concept was

startling. It meant nothing less than that the very first flight would be conducted with

all three live stages of the giant Saturn V. Moreover, in order to maximize the payoff

of that first flight, George said it should carry a live Apollo command and service

module as payload. The entire flight should be carried through a sophisticated trajectory

that would permit the command module to reenter the atmosphere under conditions

simulating a return from the Moon.

It sounded reckless, but George Mueller's reasoning was impeccable. Water

ballast in lieu of a second and third stage would require much less tank volume than

liquid-hydrogen-fueled stages, so that a rocket tested with only a live first stage would

be much shorter than the final configuration. Its aerodynamic shape and its body

dynamics would thus not be representative. Filling the ballast tanks with liquid hydrogen?

Fine, but then why not burn it as a bonus experiment? And so the arguments

went on until George in the end prevailed.

In retrospect it is clear that without all-up testing the first manned lunar landing

could not have taken place as early as 1969. Before Mueller joined the program, it had

been decided that a total of about 20 sets of Apollo spacecraft and Saturn V rockets

would be needed. Clearly, at least ten unmanned flights with the huge new rocket would

be required before anyone would muster the courage to launch a crew with it. (Even

ten would be a far smaller number than the unmanned launches of Redstones, Atlases,

and Titans that had preceded the first manned Mercury and Gemini flights.) The first

manned Apollo flights would be limited to low Earth orbits. Gradually we would inch

our way closer to the Moon, and flight no. 17, perhaps, would bring the first lunar

landing. That would give us a reserve of three flights, just in case things did not work

as planned.

| | |

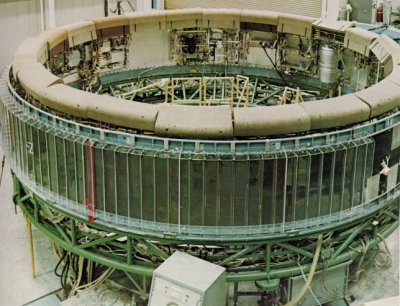

An Instrument Unit being readied for checkout at the IBM facility in Huntsville. A cylinder

22.7 feet across and 3 feet high, the structure

consists of 24 panels with stiffening rings at the

top and bottom. The units that perform the

guidance, control, and telemetry functions for

the Saturn are mounted to the inside of the

cylinder. The foam rubber pads at the top, and

the plastic strips around the outside, are for

protection during manufacture.

|

Mueller changed all this, and his bold telescoping of the overall plan bore

magnificent fruit: With the third Saturn V ever to be launched, Frank Borman's

Apollo 8 crew orbited the Moon on Christmas 1968, and the sixth Saturn V carried

Neil Armstrong's Apollo 11 to the first lunar landing. Even though production was

whittled back to fifteen units, Saturn V's launched a total of two unmanned and ten

manned Apollo missions, plus one Skylab space station. Two uncommitted rockets

went into mothballs.

| | |

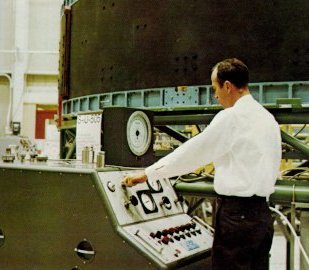

Pressure test during predelivery checkout of

an Instrument Unit at the IBM facility. This IU

was destined for Saturn vehicle 505, which

launched the Apoilo 10 mission. On the launch

pad, the IU, which weighs two tons, sits atop

the third (S-IVB) stage, with the Apollo spacecraft directly above it.

|

But let us go back to 1962. To develop and manufacture the large S-11 and S-IVB

stages, two West Coast contractors required special facilities. A new Government plant

was built at Seal Beach where North American was to build the S-11. S-IVB development

and manufacture was moved into a new Douglas center at Huntington Beach,

while static testing went to Sacramento. The Marshall Center in Huntsville was also

substantially enlarged. A huge new shop building was erected for assembly of the first

three S-IC stages. A large stand was built to static-test the huge stage under the full

7,500,000-pound-thrust of its five F-1 engines. These engines generated no less than

180 million horsepower. As about 1 percent of that energy was converted into noise,

neighborhood windows could be expected to break and plaster rain from ceilings if the

wind was blowing from the wrong direction or the clouds were hanging low. A careful

meteorological monitoring program had to be instituted to permit test runs only under

favorable weather conditions.

Although the most visible and audible signs of Marshall's involvement in Saturn V

development were the monstrous and noisy S-IC engines, equally important work was

done in its Astrionics Laboratory. The Saturn V's airbearing-supported inertial guidance

platform was born there, along with a host of other highly sophisticated electronic

devices. In the Astrionics Simulator Facility, guidance and control aspects of a complete

three-stage flight of the great rocket could be electronically simulated under all

sorts of operating conditions. The supersonic passage of the rocket through a

high-altitude jet stream could be duplicated, for instance, or the sudden failure of one of

the S-11 stage's five engines. The simulator would faithfully display the excursions of the

swivel-mounted rocket engines in response to external wind forces or unsymmetrical loss of

thrust, establishing the dynamic response of the entire rocket and the resulting

structural loads.

| | |

Super Guppy, bigger sister of the aptly named Pregnant Guppy, was the only airplane in

the world capable of carrying a complete S-IVB stage. Both aircraft were built by John M.

Conroy, who started with the fuselages of two surplus Boeing C-97 Stratocruisers, ballooned out

the upper decks enormously, and hinged the front sections so that they could be folded back

110 degrees. Super Guppy flew smoothly at a 250-mph cruising speed, and its cargo deck

provided a 25-foot clear diameter. Below, a finished S-IVB stage is being unloaded onto a cargo

lift trailer at Kennedy Space Center.

|

The Saturn V's own guidance system would guide the Apollo flights not only to an

interim parking orbit but all the way to translunar injection. It fed position data to the

onboard digital computer, which in turn prepared and sent control signals to the

hydraulic actuators that swiveled the big engines for flight-path control. As propellant

consumption lightened the rocket, and as it traversed the atmosphere at subsonic and

supersonic speeds, the gain settings of these control signals had to vary continuously,

for proper control damping. Serving as the core of the Saturn V's central nervous system,

the computer did many other things too. It served in the computerized prelaunch

checkout procedure of the great rocket, helped calibrate the telemetry transmissions,

activated staging procedures, turned equipment on and off as the flight proceeded

through various speed regimes, and even watched over the cooling system that stabilized

the temperatures of the array of sensitive blackboxes within the IU. So although the

working flight lifetime of the Saturn computer was measured in minutes, it performed

many exacting duties during its short and busy life.

| | |

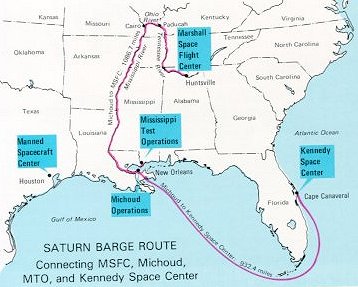

Bulky but fragile, huge launch-vehicle stages could not travel by

rail or public road; tunnels, bridges, and low wires would have

dictated endless detours. Right, even a comparatively small Saturn I

wasn't easy to back into its barge at Huntsville. Below, a rocket-laden

barge is escorted by two tugs through Sun-bronzed waters.

The biggest California-built parts of Saturn V voyaged by ship

through the Panama Canal and across the Gulf of Mexico.

|

In planning the lunar mission, why did we plan to stop over in a parking orbit?

The reason was twofold: For one, in case of a malfunction it is much easier and safer

for astronauts to return from Earth orbit than from a high-speed trajectory carrying

them toward the Moon. A parking orbit offers both crew and ground controllers an

opportunity to give the vehicle a thorough once-over before committing it to the long

voyage. Second, there is the consideration of operational flexibility. lf the launch came

off at precisely the right instant, only one trajectory from the launch pad to the Moon

had to be considered. But as there was always the possibility of a last-minute delay it

appeared highly desirable to provide a launch window of reasonable duration. This

meant not only that the launch azimuth hand to be changed, but due to Earth rotation

and to orbital motion the Moon would move to a different position in the sky. A parking

orbit permitted an ideal way to take up the slack: the longer a launch delay, the

shorter the stay in the parking orbit. Restart of the third stage in parking orbit for

translunar injection would take place at almost the same time of day regardless of

launch delays. (As it happened, all but two of the manned Apollo-Saturns lifted off

within tiny fractions of a second of being precisely on time. One was held for weather

and the other was held because of a faulty diode in the ground-support equipment.)

Why was the big rocket so reliable? Saturn V was not overdesigned in the sense

that everything was made needlessly strong and heavy. But great care was devoted to

identifying the real environment in which each part was to work - and "environment"

included accelerations, vibrations, stresses, fatigue loads, pressures, temperatures,

humidity, corrosion, and test cycles prior to launch. Test programs were then conducted

against somewhat more severe conditions than were expected. A methodology was

created to assess each part with a demonstrated reliability figure, such as 0.9999998.

Total rocket reliability would then be the product of all these parts reliabilities, and had

to remain above the figure of 0.990, or 99 percent. Redundant parts were used whenever

necessary to attain this reliability goal.

Marshall built an overall systems simulator on which all major subsystems

of the three-stage rocket could be exercised together. This facility featured replicas of

propellant tanks that could be loaded or unloaded, pressurized or vented, and that duplicated

the pneumatic and hydraulic dynamics involved. Electrically, it simulated the

complete network of the launch vehicle and its interfacing ground support equipment.

|