TESTING AND RETESTING TO GET READY FOR FLIGHT

We tested for "sneak circuits" (inadvertent electrical paths), discovered some, and made changes. We ran a "failure mode and effects analysis" - a search for all the "what happens if's" - and made more changes. We tested, and retested, and changed and fixed and tested again. We set off small explosive charges inside the burning rocket engines, and to our horror found the all-important LM ascent engine was prone to catastrophic instability - a way of burning that could destroy the engine on takeoff and leave the astronauts stranded on the Moon. Much to the consternation of my bosses in Washington, we sent out new bids and selected a different contractor who built a new engine faster than anyone believed possible. But it worked.No detail was too small to consider. We asked questions, received answers, asked more questions. We woke up in the middle of the night, remembering questions we should have asked, and jotted them down so we could ask them in the morning. If we made a mistake, it was not because of any lack of candor between NASA and contractor, or between engineer and astronaut; it was only because we weren't smart enough to ask all the right questions. Every question was answered, every failure understood, every problem solved.

We built mockups of the entire spacecraft, and tried to set them on fire. If they burned, we redesigned, rebuilt, and tried again. By vibration we tried to shake things apart; we tested in chambers simulating the vacuum of space, the heat of the Sun, and the cold of the lunar night. We subjected all systems to humidity and salt spray, to the noise of the booster, and the shock of a hard landing. We dropped the command module into water to simulate normal landings and on land to test for emergeng landings; we plopped the lunar module on simulated lunar terrain. We overstressed and overloaded until things broke, and if they broke too soon, we redesigned and rebuilt and tested again.

The final exam came in flight. First the command module was tested with only the launch-escape tower, against the possibility of a Saturn exploding on the launch pad. Then we launched the CSM on a special booster, the Little Joe II, to see whether it would survive if the Saturn should fail in the atmosphere, when air loads are at their peak. (There is a big difference between manned and unmanned fllght. If the launch vehicle should stray off course while lifting an automated payload, the range safety officer could press a button and destroy booster and payload together; in manned flight the spacecraft would first be separated from the errant booster, which would then be blown up before it wandered off, leaving the CM to be carried to safety by the launch escape tower. This separation maneuver demanded the utmost in speed and power.)

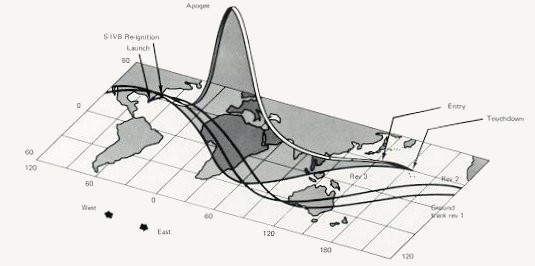

The CSM, unmanned was flown twice on the Saturn IB (1,600,000 pounds of thrust). Then, on November 9, 1967, came the most critical test of all: Apollo 4, the first flight of the Saturn V (7,500,000 pounds), would subject the CSM to the lunar return speed of 25,000 mph. After achieving an altitude of 10,000 miles, the spacecraft's engines drove Apollo back down into the atmosphere at unprecedented speed. Temperatures on the heat shield reached 5000° F, more than half the surface temperature of the Sun. The heat shield charred as expected, but the inside of the cabin remained at a comfortable 70° F. A major milestone had been passed.

Apollo 5 on January 22, 1968, was the first flight test of LM - an unmanned flight in Earth orbit that put the lunar module through its paces. There were problems. The computer shut down the LM's descent engine prematurely on its first burn. But then the flight controllers on the ground took over and continued the flight with an alternate mission. Now another question arose: Should we repeat this flight? Grumman felt we should, I disagreed. After considerable technical debate, we decided that the next flight with LM would be manned - which it was, 14 months later.

Apollo 6, three months after Apollo 5, was to be a simple repeat of Apollo 4, but it wasn't. The Saturn had problems, and so did the spacecraft adapter - that long conical section which joined the CSM to the booster, and which also served as LM's cocoon. (The spacecraft itself did a beautiful job.) After a fantastic piece of detective work by Don Arabian, our chief test engineer, wo found a flaw in the manufacturing of the honeycomb structure of the adapter, and how to fix it.

October 11, 1968. Eichteen months since that day in the pilot's lounge at Washington Airport when I said yes, I would take on Apollo. Eighteen of the greatest months an engineer could ask for. In that time 150,000 Americans had worked around the clock, dedicating their skills and their lives to forge two of the most magnificent flying machines yet devised: CSM and LM. It was a beautiful morning in Florida, just the kind of morning for another launch. This time Apollo was ready for its men.

|

| Charred but perfectly intact, the CM here had passed its most severe test of reentry at a speed of 25,000 mph. From left, Ralph Ruud, Dale Myers, George Low, and Robert Gilruth. |

|

| This is the flight path of the Apollo 4 spacecraft above during its trial. First, its booster carried it to its peak altitude, and then its own big rocket accelerated it down into the atmosphere until it reached reentry speed. To an observer it would have appeared like a giant meteorite in the sky. |

| Next |