The Troubled Launching of SA-5, January 1964

The block II version of Saturn I (SA-5 through SA-10) represented a sizable increase in launch requirements over block I. Additional RF links, calibrations, and systems tests in the two-stage rocket nearly doubled launch checkout time. [see table 1, chapter 2-1]

The greatest change in the block II rocket was the addition of a hydrogen-fueled second stage. Douglas Aircraft Corporation had won the contract for the S-IV stage in April 1960, five months after NASA adopted the Silverstein Committee's recommendation to use liquid hydrogen in the Saturn's upper stages. The 13-meter stage had six Pratt & Whitney RL-10 engines, the same power plant that NASA intended to use in the Centaur rocket. Confidence in the S-IV stage originally stemmed from expectations that Centaur tests would prove the effectiveness of the engine long before SA-5. As things worked out, the first successful Centaur launch came in November 1963, more than two years behind schedule and only two months ahead of the SA-5 launch.

SA-5 differed in other ways from its Saturn predecessors. Engineers had increased the 340,500-kilogram capacity of the S-1 first stage by more than 31%. Each H-1 engine had been uprated to its intended 836,600 newtons, giving that stage its full thrust. Marshall had also attached eight fins to the base of the S-1 stage, four stubby fins and four longer ones that extended 2.7 meters from the rocket. These provided additional aerodynamic stability (a decision prompted by possible use in the Dyna Soar program). The guidance and control instruments for both stages flew in an experimental instrumentation unit above the S-IV stage. The payload for SA-5 was a Jupiter nosecone.24

The postlaunch celebration for SA-4 was barely over when Hans Gruene's Launch Vehicle Operations team turned its attention to the block II series. The first order of business was fitting LC-37B with a dummy SA-5 vehicle. The dummy stages were erected and mechanical support equipment tests completed by the end of April 1963. In the first two propellant flow tests, the transfer system kept the hydrogen below 20 kelvins (-253 degrees C). Chemical analysis revealed contaminants, but the liquid hydrogen cleared up on the third test, saving the launch team a detailed investigation. There were a number of routine problems such as leaking LOX lines, freezing LOX vent valves, and inoperative gauges. Only one major change was required, a modification of the baffles in the S-1 stage LOX tank. There was time for this since the SA-5 launch date had been moved from August to December.25 After the wet tests were completed in late June, NASA flew the S-IV dummy stage back to California aboard a modified B-377 aircraft.*

The Pregnant Guppy, a modified B-377 aircraft used to airlift Saturn stages, July 1963.

Gruene's launch team erected the Saturn booster on 23 August and during the next 30 days performed mechanical system tests, calibrations for the instruments, and telemetry and RF tests. The only serious difficulty was one that apartment dwellers can appreciate - four service structure elevators that were frequently out of order and usually crowded. In the upper levels of the 90-meter-high, open structure, elevator cables were exposed to rain and wind. Maintenance problems were inevitable. In September 1963 the combined load of facilities contractors (outfitting the service structure) and SA-5 launch technicians strained the elevators' capacity. Gruene informed Debus on the 12th that "elevator usage is now critical and may become intolerable when checkout activities require more personnel."26 Gruene hoped to finish outfitting the service structure after the normal workday to alleviate the problem.

In Sacramento, Douglas engineers completed four weeks of poststatic checkout of the S-IV on 10 September. The second stage was removed from its test stand, loaded aboard the B-377, and flown to Cape Canaveral. Douglas personnel gave the stage a thorough inspection, including the use of a sound probe to detect debonding of tank insulation. The probe was moved back and forth over the outer surface of the stage, its signal reflecting back from the inner side of the tank skin into the probe's sensing device. An oscilloscope showed both the output signal and the echo. Welds or any other irregularities stood out clearly. Heavy winds and rain that struck the Cape the following week did not halt S-IV activities in hangar AF. However, out on pad 37B the telephones failed, the service structure elevators were temporarily shut down, and the launch team lost three days of work.27

Transporting the SA-5 first stage to pad 37B.

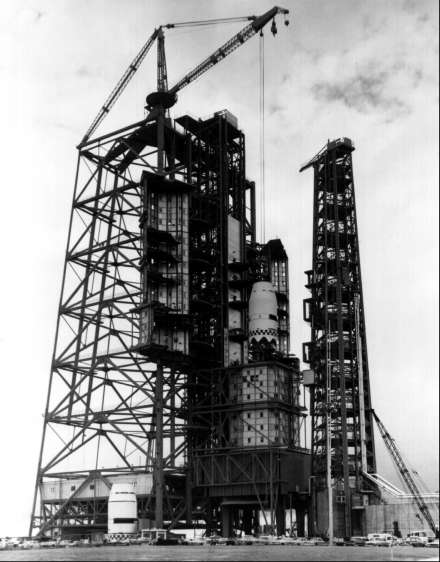

Erecting SA-5. The live S-IV stage is being lowered into position, replacing the dummy spacer, which is on the ground (left).

Operations reached a hectic pace in mid-October. After the S-IV stage was erected on the 11th, Robert Moser's office revised the launch schedule to give Douglas a week longer for S-IV checkout and modifications and a combined LOX-LH2 tanking test. Moser maintained the 6 December launch date by compressing the time allowed for launch vehicle tests in November. Even with the extra week, Douglas found the test requirements more than it could handle in a 16-hour day. On 17 October the California firm asked for around-the-clock operations until the propulsion tests were completed. Gruene, hard pressed to support the S-IV stage operations, reluctantly agreed.28

* Because of its enlarged fuselage, the plane was popularly known as the "Pregnant Guppy."

| Next |