Hold-Down Arms and Tail Service Masts

Four hold-down arms had to secure the Saturn V firmly on the mobile launcher during assembly, transportation to the launch site, and its stay on the launch pad in all kinds of weather. These devices also had to have the strength to hold down the launch vehicle after ignition, until all engines registered full thrust. Then they automatically and simultaneously released the Apollo-Saturn for liftoff. They did not, of course, have to overcome the full power of all the engines; the great weight of the fueled vehicle counteracted much of the thrust, As an indication of the unusual design requirement, James D. Phillips of KSC Launch Support Equipment Engineering Division won the 1965 steel-casting design contest sponsored by the Steel Founders Society of America for the design of the casting forming the base for the hold-down arms.36 The arms would weigh over 18 metric tons each; the base was to be just under two meters wide, and not quite three meters long. They would stand 3.35 meters high. Nevertheless, in contrast to the huge Saturn vehicle, the hold-down arms seemed much too small to anchor - even momentarily - the huge rocket. On 17 February 1964 the KSC Procurement Division issued a contract to Space Corporation, Dallas, for the manufacture of 16 hold-down arms for the mobile launchers. The cost of the fixed price contract was $676,320, with completion date set for 25 July 1965.37

Schematic of hold-down arm. The leverage produced 350 metric tons of force at C. The solid lines show the arm at work; the dotted lines represent the condition following release of the Saturn, when the linkage has collapsed and the blast hood closed.

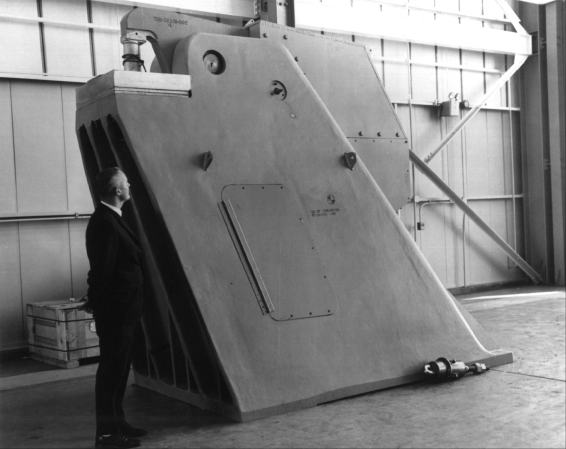

A hold-down arm ready for installation on a mobile launcher, November 1964.

The first hold-down arm arrived at Huntsville on 31 October 1964, and testing began on 20 November. Due to a strike at a subcontractor's plant, the second arm, scheduled for delivery on 19 November, came on the 28th. On 17 May 1965, engineers tested the ability of the first hold-down arm to sustain a vertical thrust of 725,747 kilograms. After the successful completion of all other tests on this arm on 25 May, workers installed and aligned an operational set of hold-down arms on launcher 3 at KSC. The other hold-down arms were ready by the end of the year.38

Tail service mast for delivering propellants and electrical connections to the first stage.

In addition to the four hold-down arms, three tail service masts would also stand on the base of each launcher. These provided support for electrical cables, propellant loading lines, hydraulic lines, and pneumatic lines servicing the first (S-IC) stage of the Saturn V. At liftoff a sequencer would hydraulically retract them, swinging them up and away from the Saturn V. A protective hood would fold over the umbilical connections on the end of each mast, protecting the connectors from the rocket engine's exhaust. After constructing and testing a prototype of these devices, the American Machine & Foundry Company of York, Pennsylvania, built the tail service masts.39

| Next |