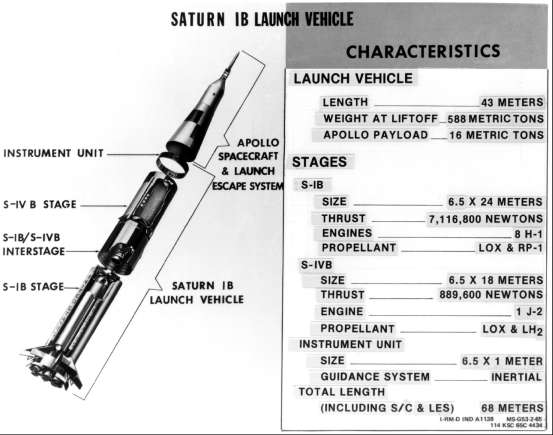

The Apollo-Saturn IB Space Vehicle

Schematic of Saturn IB, with characteristics.

The LC-34 modifications were designed to accommodate a 68.2-meter Apollo-Saturn (AS-201), which could count as many "firsts" as any of the Saturns. Its upper stage (S-IVB) would be the first to use a hydrogen-burning J-2 engine (900,000 newtons or 200,000 pounds of thrust); it had a new instrument unit, nerve center for guidance and control; it was the first to carry a live (though unmanned) Apollo command module, powered by a service module, the engine of which was intended to start and restart in space. Perhaps most important, and certainly most troublesome, was the first installation of an on-line, automated checkout system. These innovations were the cause of many delays in the launch program - and justification for the delays, as well: what was worked out successfully for AS-201 would be available for Saturn V.9

The first piece of AS-201 to arrive at the Cape was Chrysler Corporation's S-IB stage. It arrived from the Michoud Assembly Facility aboard the barge Promise 14 August 1965. It was the first Saturn to enter the Banana River and KSC through the Canaveral locks. The new S-IB was basically the S-I stage, redesigned to reduce weight and increase thrust. The empty weight was 42,048 kilograms, some 11% lighter than the S-I. North American Aviation had improved the operation of the eight H-1 engines so that the stage produced 7,200,000 newtons (1,600,000 pounds of thrust), some 6% greater than the S-I. The stage would reach an altitude of 60 kilometers in 2.5 minutes of flight.10

The S-IVB second stage went through its acceptance test at the Douglas Aircraft Company's Sacramento Test Center on 8 August and made its first appearance at the Cape on 1 October. While the Cape had welcomed an old friend back in the S-IB, the S-IVB was a newcomer. And an important newcomer: not only would it serve as second stage in AS-201, but it would also be the third stage in the all-important Saturn V. Its single J-2 engine (by North American Rocketdyne Division), burning 7.5 minutes, could put it into earth orbit (though not on AS-201); as the Saturn V third stage, it would put Apollo into translunar trajectory.

Spacecraft components arrived at the Cape in late October, the command module on 25 October and the service module two days later. The base of the service module housed the spacecraft's main propulsion unit, a single engine that used a half-and-half mixture of unsymmetrical-dimethylhydrazine and nitrogen tetroxide to achieve 97,400 newtons (21,900 pounds of thrust). It would be ignited twice on the AS-201 flight, once for three minutes and again for ten seconds. Beneath it was the vehicle's only big piece of boilerplate, the lunar module adapter joining the service module and the S-IVB instrument unit. On AS-201 it consisted of aluminum alloy bracing; in future flights it would house the lunar excursion module.11

| Next |