A Service Structure for Saturn

MFL's Mechanical Branch, meanwhile, considered the assembly, transport, and service of the launch vehicle. The March 1959 criteria book called for checkout of the Saturn stages in hangar D in the Cape's industrial area, transfer to the pad, and erection and mating of the stages on the pad, The plan required extensive modifications to hangar D, as the booster's size necessitated an increase in hook height from 8 to 13 meters. This additional space could be provided by cutting the roof structure from its columns, jacking the entire roof up as one assembly, and building up the columns.13

Some of the Development Operations Division's plans for a Saturn service facility, drawn in terms of a 25-meter booster and limited funds, seem primitive in contrast with the eventual structure. One early study proposed to eliminate service platforms by designing the upper stages with sufficient work space inside the rocket. Another short-lived scheme lowered platforms down over the launch vehicle, attaching them to the rocket's outer surface at the required working levels. Workers would ride elevator stands up to the work platforms. In a November 1958 memorandum, Albert Zeiler scoffed at the notion of men servicing a rocket from a little platform, high above the ground. He said it would be "practically impossible" to perform assembly and checkout tasks, especially in bad weather. In addition, the rocket would be exposed to rain and high winds; in the event of the latter, it would have to be secured by guy wires.14

He recommended instead a large stand with lifting equipment to assemble and erect the booster and upper stages. Service platforms to support personnel and equipment, elevators, and weather protection would be incorporated in the stand.

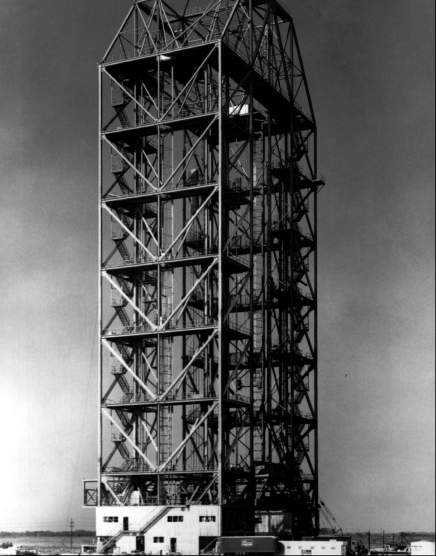

The service structure, LC-34.

MFL awarded the criteria studies for the launch complex and service structure to the Miami firm of Maurice H. Connell and Associates. The Miami architects, veterans of the Redstone program, completed both studies by mid-March 1959. At a conference later that month, Saturn engineers agreed to complete design work by 1 August 1959. The conference set a 1 July 1960 target date for construction of the complex, excepting the blockhouse and service structure.15

Connell and Associates had completed the criteria studies and moved into the design phase when MFL decided on major revisions in the assembly and service concepts. Prior to the criteria review, IDECO, a Dressler Industries division, had approached MFL with a proposal for a tubular steel service structure. It was designed in the shape of an inverted U, open at both ends. IDECO's design offered several advantages: greater accessibility to the booster, a minimum hook height of 13 meters, and more flexible service platforms (the platforms telescoped in and out of the main frame design, were vertically adjustable, and could match up with various booster or upper stage diameters).16

An additional attraction of the IDECO proposal stemmed from a new MFL proposal to assemble and check out stages of the launch vehicle in a building 180 meters from the launch pedestal. The facilities people at the Cape had never really liked the idea of modifying hangar D; many thought the raised roof would collapse in a hurricane. In the new plan the staging building shared a bridge crane with the IDECO service structure. Rails at the ceiling level of the staging building matched up with the bridge crane rails at the 13-meter level in the service structure. A cutout portion in the center front of the staging building roof provided space for the bridge crane roof. The dual use of the bridge crane allowed the transfer of the stages from the staging building to the launch pedestal in one operation.17

General Medaris was impressed with the IDECO proposal and ordered an extension of the service structure study. At a 13 April meeting, MFL directed Connell representatives to prepare a new design incorporating 14 function capabilities of the IDECO proposal. The Miami firm satisfied this requirement in ten days. The design called for a structure of girders and platforms shaped like an inverted U 95 meters high. The service structure was 40 meters wide, including the 17-meter open space where the structure extended over the launch pedestal. A bridge crane supported 40- and 60-ton hoists at a 75-meter hook height. Each hook had a forward reach of 9 meters and a lateral reach of 6 meters. Seven fixed platforms were housed within the tower legs, each providing 73 square meters of working area. Each half of the six enclosed retractable platforms had a capacity of 12 persons and 272 kilograms of equipment, The platforms were vertically adjustable from the 25-meter to the 68-meter level. Three elevators provided a 227-kilogram lift.18

Construction bids followed in June. Since assembly and service methods were still not firm, the contract called for additional design work. Kaiser Steel Corporation's $3.9 million bid, $400,000 less than an IDECO proposal, won the contract. Kaiser formally began work on 14 August 1959, but construction did not start until the following summer.19

Brick and mortar work on the new complex proceeded satisfactorily, slowed little if at all by the still meager Army appropriations and the prospects of major administrative changes taking form in Washington. In early June 1959 the Western Contracting Company began hydraulic-fill operations at the pad. A proprietary process, vibroflotation, was used to compact the fill, The Vibroflot machine consolidated the marshy soil by simultaneous vibration and saturation; the machine vibrated the sand with ten tons of centrifugal force as it pumped in more water than the surrounding soil could absorb. The sand formed a dense mass, the excess water floating fine particles to the surface. Workmen shoveled in backfill (roughly 10% of the total volume compacted) to increase the density. Vibroflotation on LC-34 required 5,350 cubic meters of fresh sand to provide compact soil 8.5 meters deep. In late November, the Henry C. Beck Construction firm started work on the pad facilities. Three hundred and twenty meters to the southeast, the blockhouse was taking shape.20

13. Zeiler interview, 24 Aug. 1972; Connell and Assoc., Launch Facility Criteria, p. 2-9.

18. MSFC, SA-1 Data Book, pp. 131-33.

| Next |