500-F Up and Out

KSC passed its second major hurdle in March, erecting the 500-F launch vehicle in high bay 1. Crane operators began practice runs in February, using a 9.5-meter spherical water container. Stanley Smith, Bendix senior engineer for the crane and hoist group, simulated the different weights of the Saturn stages by varying the amount of water. On 15 March the 250-ton crane lifted the 500-F first stage from the transfer aisle to a vertical attitude and up 59 meters. After moving the S-IC-F stage through the opening in the bay trusswork, the crane operators lowered it gently to the platform of the mobile launcher. The second stage, S-II-F, followed the same route on the 25th, when it was mated with the first stage. The third stage and instrumentation unit joined the stack before the end of the month. Concurrent exercises out on pad A tested the interfaces between mobile launcher 3 and the pad. The final test pumped 1,135,000 liters of water through the deluge system on the launcher.45

The site activation schedule allowed three weeks in April for GETS (Ground Equipment Test Set) tests. The exercises, a long standing Marshall policy, verified Saturn V ground support equipment before its initial hookup with the launch vehicle, in this case the 500-F test vehicle. The checkout also acquainted stage-contractor crews with the equipment. Problems with the Brown Discrete Control System and the Sanders Saturn V Operational Display System threatened to delay the start of the GETS tests on 8 April. The Brown equipment, located in the launch control center, controlled the flow of signals into and out of the RCA 110 computer in the launch control center. The Sanders system in the firing room ran a series of consoles that displayed data from the control center computers for operational use. KSC technicians had the display systems working by 1 April.

The first week of GETS tests featured power and network checks of all electrical support equipment. The following week's tests of ground equipment included measuring and radio frequency, pneumatic systems, propellants, and the emergency detection system. The third week KSC conducted tests of the digital data acquisition system, camera control, and leak detection and purge panels. Although the contractors ran two-shift operations, shortcomings, particularly with the RCA 110 computer, forced a fourth week of individual stage tests. Integrated GETS tests followed during the week of 2 May.46

In mid-April the Site Activation Board added another to its list of major problems: the installation of electrical and pneumatic lines on mobile launcher 1. Late deliveries and last-minute modifications from Huntsville and Houston threw the Pacific Crane and Rigging crews behind schedule. Despite 14-hour shifts, seven days a week, the crews made little headway. A "tiger team," composed of members from KSC's Engineering Division, the stage contractors, and Pacific Crane and Rigging, supervised the rush work. As the power-on date of 13 May approached, pipefitters abandoned their practice of turning over complete pneumatic systems to operations personnel. They began working line-by-line to meet specific 500-F milestones. As late as 3 August, 39 electrical cables and 232 pneumatic lines remained to be installed. Temporary fittings and work-arounds, however, prevented any major delay in test dates.47

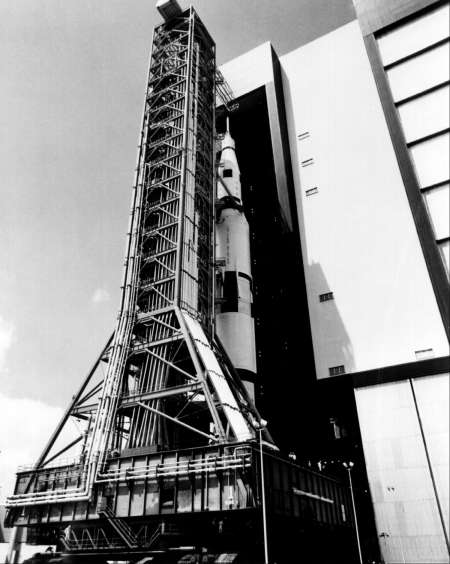

AS-500F, the facilities checkout dummy vehicle. (1) Emerging from the assembly building, as seen from the ground, 25 May 1966.

AS-500F, the facilities checkout dummy vehicle. (2) As seen from the air, 25 May 1966.

AS-500F, the facilities checkout dummy vehicle. (3) Starting up the incline to the pad, 25 May 1966.

500-F rolled out from the assembly building on 25 May 1966, five years to the day after President Kennedy's challenge. Despite the attendance of many Apollo program dignitaries, the Saturn vehicle stole the show. Like the Trojan horse of old, the first glimpse of the emerging Saturn vehicle was awesome. The crawler experienced little difficulty carrying its 5,700-metric-ton load to pad A. During portions of the trip, the transporter operated at full speed - 1.6 kilometers per hour. The Saturn vehicle reached the top of the pad at dusk and was secured two hours later. Understandably, the success was a joyful occasion for KSC and the entire Apollo team. The operation proved the soundness of the mobile concept.48

Less than two weeks later, that concept received an unscheduled test under emergency conditions. In early June hurricane Alma skirted Florida's east coast. Debus put the mobile concept through its paces. At 1:00 p.m. on 8 June, he ordered 500-F back to the assembly building. Within three hours, the launch team had disconnected the mobile launcher from its moorings. Wind gusts over 80 kilometers per hour spurred the efforts. The crawler began the return trip at 5:33, taking one hour to descend the 392-meter sloping ramp. Sheets of rain and 96-kilometer-per-hour gusts accompanied the crawler team on the straightaway as they urged their ponderous vehicle to its top speed. The crew reached the assembly building at 11:43 p.m. and had the mobile launcher secure on its mounts one hour later.49

| Next |